NEWSLETTER

Sign up for GMORS latest news.

The friction characteristics of rubber parts can be result of many factors, such as the nature features of elastomers, the addition in rubber compounds, the surface finish of the molds or post-processing techniques to rubber during manufacture. Via some of controllable factors, the way to reduce friction can therefore be various and tailored for each individual application. To help customers find the best low friction solutions with GMORS, a series of lubrication methods for rubber parts will be introduced in the following article.

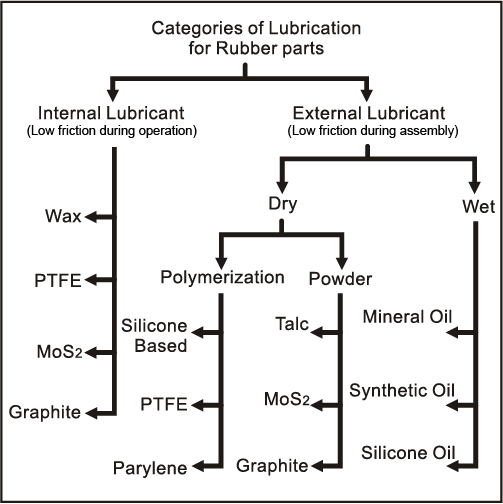

Lubrication, like many kinds of coatings or inner-lubricated, is a cost-effective option for most of customers today. It helps avoid unnecessary high cost from over strict surface requirement on tooling. Also, for standard products, it is relatively efficient and widely applicable when compare to more customized solution, like friction reduction via seal design change. GMORS lubrication solutions are categorized as diagram for reference in Figure 1 below.

Figure 1. Categories of Lubrication for Rubber parts

GMORS products mainly can be dry, wet or internal lubricated.

Wet lubrication

Wet lubrication is liquid or grease applied on product surface, and proper mineral oils, synthetic oils or silicone oil can be chosen depending on product material and work environment. Actually, many users dip or apply the parts with lubricants before assembly, and some users order the parts with lubricants applied to avoid extra work procedure. However, wet lubricant will easily pollute the production lines. Also, parts after unsealing the package must be assembled as soon as possible in case of evaporation and lubrication failure. If there are parts left, the package must be resealed carefully and stored away from direct sunlight and high temperature.

Dry lubrication

There are two types of dry lubrication. The first one is powder coating, e.g. talc, graphite, MoS2, etc. Similar to wet lubrication, powder coating carries advantages like simple work procedure and low cost but disadvantages like powder pollution[1]. As again this is not applicable in production lines that require no pollution, the second type dry lubrication , the Film-forming polymer lubrication, is therefore highly recommended.

The main advantage of “Film-forming polymer lubrication” is that it will not generate any powder as it covers the part surface with a polymer film in thickness from nanometer to micrometer. Common material with low friction is PTFE film, which normally can be in color transparent, red, orange, green, blue, gray and white. It benefits the assembly line a lot, like preventing mix-up with color added, preventing sticking and low friction for higher production efficiency. To satisfy customers best, a study has been made on advanced PTFE coating in another article.

Another type is Silicone-based transparent thin film that relatively shows better elasticity with low friction than the above. It is suggested to be used for assembly, not for dynamic service application. Though the above two coating materials will not generate pollution, but it is still not recommended for high cleanliness requirement industry.

One more type in the "film-forming" category is the Parylene. It is a coating technique providing higher bonding strength, higher cleanliness level and more uniform surface and thickness than PTFE film. Parylene coating can not only lower the friction of rubber seal, but also make rubber seal less reactive towards moisture or chemical attack. However, the cost of parylene is relatively high.

Internal lubrication

All the above are external lubrication for assembly usage. GMORS internal lubrication is suggested for customers that require dynamic usage, where the low speed abrasion or vibration may happen. With proper lubricants, e.g. wax, PTFE (for high pressure), graphite or MoS2, added to rubber compounds, they will permeate to the part surface during usage and bring long-term lubrication effect, making the product life longer.

Among all these options, the best solutions will always depend on what you need. Some may need simple powder coating for easy handling, some may need internal lubrication for dynamic usage, and others may need strict cleanliness control or several coloring to identify similar parts. In addition, any applications with high standard or specific requirement are highly recommended to consult us for further details in your working conditions.

GMORS Solutions

To offer customers the total satisfaction service, and at the same time, the uppermost balance on quality, low defect rate and cost for each kind of applications and usage requirements, GMORS suggests:

Some other post processing method to the surface can be of your choice. Please contact GMORS if the surface treatment you need is not listed here.

[1]Talc is white powder; graphite and MoS2 are both black powder while MoS2 shines some metallic gloss.

Sign up for GMORS latest news.

Copyright ©GE MAO RUBBER INDUSTRIAL CO., LTD. All rights reservedTerms and Conditions|Privacy policy